Software Engineering / OEM

Software development and Ready to Market SW solutions

Our SW toolbox “Fortress” allows us to customize software solutions exactly quickly for Motion Control, Lighting Control, Autofocus, Object Tracking, Memory Management and Big Data analysis.

We program with Vision Builder NI, Open CV, C++, Halcon and more to choose from to provide the best solution for you.

You may also want to look at solino for your software needs.

Workflow Management Solutions

Since we have internal in-house hardware and software development capabilities, we can design complete industry 4.0 stations for our partners/customers. The idea behind this to integrate different IoT sensors to monitor, test, analyse and make decisions to take quality, throughput and documentation to a new level.

Complete IoT Laboratory Solutions

Complete laboratory solutions with survey, instruction, documentation and help functions. For biological applications, we offer plug-and-play imaging modules or dual stations for digital microscopy on-site. From our own Opto software framework, we can extract only the drivers and plug-ins that are required.

l Designed for digital support of mechanical assembly work

l Unique opto-design/own production

l 3D runtime imaging module

l “Pick to Light” scanner solutions

l High resolution 2D imaging modules

l Complete software interface and analysis

Opto manufactures and sells Imaging Modules and provides software support but not the complete systems.

Assistance with Assembly function

Assembly assistance solutions for production lines or training purposes with the aim of:

l Modular (All type of sensors possible)

l Plug-and-Play (developed in cooperation with customer standards)

l Increase in throughput

l Quality improvement

Opto only offers these solutions and services to OEM partners and not directly to “Open” markets.

User Interface Design

Ease of use and intuitive operation of a software solution is crucial and integrate your own CI. We offer this service to our OEM partners and support them with the integration of our imaging modules.

Mobile Interface Design

It is becming more and more important to have mobile access to your machine and process especially with regards to “predictive maintenance”.

For this reason, we deliver APP designs for controlling and reading out imaging modules such as IoT devices.

Process Recording and Control

With our own Fortress framework, we are also able to control an intellectual workflow process for various applications:

l AQT (Assembly/Quality Control/Throughput) assistance systems

l Digitization for your laboratory environment

l Data and Network Management

Image Analysis

In the last 40 years, we have developed countless market-specific solutions that have been integrated into our own Opto Framework that now provides you with plug-and-play job modules.

The above are some solutions that can be easily combined to create new sensors for you.

Counting Bacterial Colonies

Counting and analysing colony growth in petri dishes requires fast, high-resolution image acquisition.

The differentiation in size and greyscale and the identification of colony families are further requirements in addition to statistical DATA mining.

Mechanical positioning autofocus or other automation often must be adapted to the application. Everything can be realized with our own framework and Imaging Modules.

ALL FROM A SINGLE SOURCE.

Quality Control of Pharmaceutical products

Many quality controls must take place during drug development and manufacturing of pharmaceutical products.

l Measure the size and roundness of tablets and pills

l Detection of verification of the correct color

l Analysis of the homogeneity of blister packs

l Classification of defects and anomalies

Control of Electronic Assemblies

For the control of SMD board or wafers, Imaging modules offer the correct image acquisition and provide software for:

l Learning from a master reference board

l Online verification of the presence and alignment of components

l Barcode reading of product details

l SMT control

Detection of impurities in transparent materials

The quality control of plastic strips, which are used for example, in the manufacture of high-voltage electrical cables, requires:

l Detection of holes and defects

l Determining the position, level and classification of contaminants

l Automatic detection of anomalies (color and etc.)

l Statistical analysis of the results, including data export

Automated Cell Counting

To analyse cells, it is necessary to control them where they occur. At the chip level or in microfluidic channels or in petri dishes or microtiter plates. We offer you the right image acquisition module and can support you with special software functions for your application.

l Track the morphology and movement of cells in real time

l Classification and identification of cells with specific fluorescent markers

l Automated counting of cells

l Integration of the cell analysis in existing microfluidic structures

Tools and Screw testing

Over the years, we have supported system integrators in quality control solutions with special Imaging Modules and corresponding software code:

l Finding anomalies with solino

l Geometric measurements

l Documentation and DATA management

l Statistical analysis of the results

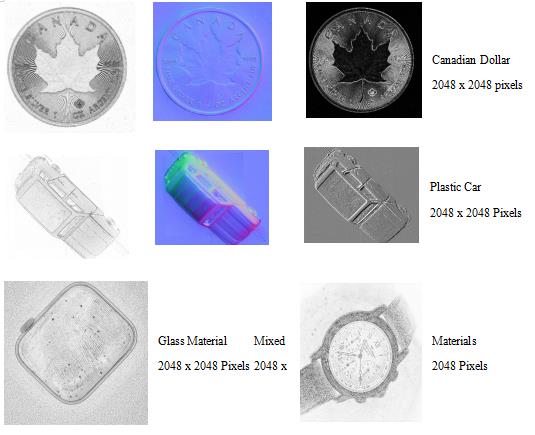

Computer-Aided Imaging / Computational Imaging

Computational imaging means extracting additional information from standard images. It requires a deep understanding of the application and we often assist only as an extended development partner.

Solino is our own algorithm for digitizing the human perception of products and High-Resolution effects are possible.

Our Imaging Modules are perfect for Computer-Aided Microscopy.

solino CPI

CPI is a software solution for calculating a (specific) image from an image set, considering the consistency and calibration of the image input.

The acquisition consistency leads to BRDF information and CPI allows this information to be broken down into sub-layers with an image as the sub-layer.

Each (particular) image is the result of several operations processing from the distribution of pixel values. To improve quality control processes, CPI offers a picture gallery to investigate surface anomalies as a step towards an automated inspection that is human controlled and operated by AI.

“Deep Learning” and AI

AI has arrived in society. We are in the middle of the 4th Industrial Revolution and are confronted with fundamental changes in our global economic structure. The ongoing corona crisis will also fundamentally change the way we live and work.

The vulnerability of existing processes will perhaps give a huge boost to digitalization and automation and reduce prejudices against new ways.

Just like in society, industry should also be able to test this insight in mature new methods. There are already many successful examples in medical technology, drug research and pathology.

In production, every quality assurance officer wants to have a statement on product quality as quickly as possible to control his production process. Unfortunately, determining the shape and position, the colour, the tribological properties and all other criteria that make up the function of a product is currently only possible with different measuring instruments, one after the other, and requires a lot of time and money.

What if there were a way to combine all this with a simple, inexpensive, non-contact, fast and environmentally independent analyser? Ingenious, but unrealistic.

Until now.

The idea is to take human evaluation of surfaces as the basis for digitization. Together with the mass available measurement cycles and experience about the product and the information about it known for years, a network is fed and with a solino reflex analysis anomaly are detected to an ideal situation. The resulting data set contains all product-relevant information, which only needs to be analysed and classified after changes.

This makes it possible to work out the traceability to standards, to generate measurement results or to use the data directly for production control. This would close the control loop for artificial intelligence. Sounds simple, but it is. Nevertheless, it will take some time before we believe these results, because the decisions about good and bad are not traceable according to standards but have been created in the data room. But also, Google bases the decision cat or dog not on image information but on the comparison of its digital twin and is not bad at it. However, Google's dataset is only a fraction of the one available here, and the tolerances between good and bad are also simpler.

As you can see here in the example, this information can be easily put back into image information and e.g. only the impurities can be read out according to particles or fingerprints. But this only cost computing time and requires a further analysis according to existing image analysis procedures in order to make a decision.

We have started to test deep learning tools and big data algorithms together with the unique Solino technology, which allows us to start the classification not on the basis of images but on data sets containing ALL anomalies of the test object. This enables us to use the solino technology to simulate human perception, rather than using standards to evaluate the quality of a product, as is the case with traditional defect specification solutions.

Opto is on the way to develop new AI modules based on the constantly growing imaging module family, which are equipped with our own solino technology. More than 40 years of experience in the development of cameras with integrated optics and illumination in microscopy and machine vision as well as the long tradition in programming own image processing solutions is the basis of these new modules. Currently more and more machine manufacturers, system integrators and corporations are working on integrating the plug-and-play OEM solutions around the described imaging modules from Opto into their devices and processes to achieve better results and a reduction of equipment costs in the long term.

This disruptive approach may be integrated faster than expected due to the upcoming changes and will become accepted as a replacement for traditional measurement methods. If AI can detect and analyse diseases faster and better, new vaccines can be developed faster and better, why shouldn't the results speak for themselves and prevail in traditional measurement technology as well?

Opto Viewer

Our OptoViewer is free and it comes supplied with every single Imaging Module.

It enables easy installation of the camera, control of the light sources and contains many additional functions such as:

l Simple user interface

l Camera, coaxial and ring light settings

l Preferences files

l Pre-Calibrated magnification settings

l Light adjustment

l Flat field correction

l One-click export to image file Storage

l Crosshair/grid/scale generator

l Drawing/Annotations (basics, shapes, bitmaps, text)

l Standard measuring functions

² Point to point distance

² Angle

² Focus

Download

Each imaging module is supplied with our Opto Viewer software (on request). The software is a Windows-based and the Imaging Module with its USB-C port can be connected to a PC without any complex configuration effort. Just Plug-and-play.

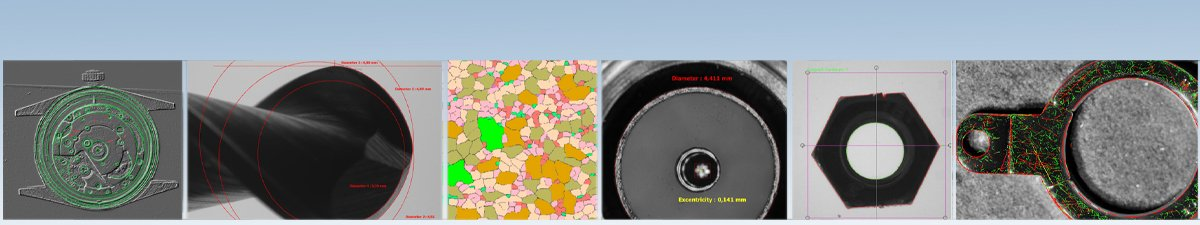

Jobs solutions

We pretty much focus on the result and not the image itself.

We merge our Imaging Modules with innovate measurement and image analysis software to create intelligent plug-and-play modules “job to be done”.

There are no additional software licenses required.

Cylinderinspector software

We have developed a special software to analyse the grinding angle and the crystalline structure of the inner walls of the cylinder. Together with the universal documentation functionality, it is the perfect job solution.

YOUR “job” solution

In the past 40 years, we have solved countless market-driven challenges. The results flow into our own Opto Framework to be able to deliver “plug-and-play” jobs modules quickly.

The chance that we have the solution for you is high.

Do not wait.

Call us.

3rd party IM compatible software packages

Opto’s software focus is on supporting the Imaging Modules and not on its own scalable software package. The following market-leading solutions have perfectly integrated the full functionality of the Imaging Module.

We are happy to announce other software solutions that works with our Imaging Modules.

NI LabVIEW Vision Library

National Instruments Vision Builder software offers hundreds of world-class image processing algorithms and image acquisitions that you can use across the entire NI hardware portfolio.

l Image capture software

l Image analysis and image processing software

l Vision libraries

l Development environments

Metlogix M3 measuring software

The Metlogix M3 one touch measurement software performs critical analysis at every stage of your manufacturing process. It is a reliable, intuitive and versatile tool in the metrology market.

l Measurement point recording via cross hairs, intelligent video tools

l Multi probe capability

l Measure, construct and define regular 2D and 3D geometrics

l And more

Image analysis “pxf workbench”

The Pixelferber Workbench is the perfect solution for high quality metallurgical applications such as:

l Analysis of the grain size

l Particle counting and analysis

l Phase proposition

l Steel inclusions

l Image analysis

Picture Gallery

Because we combine the know-how of high end optics with the disruptive solino technology, we are able to generate unique image data that can be used for modelling and research.